Standard surface

We can supply and customize a complete line of filter paper and filter cloth for industrial production especially for the coolant of metal processing and filter press production.

Filter paper is commonly used in the framed oil filter press and coolant filtration system, while the filter cloth is used in the filter press production.

Coolant Filter Paper

Plate/Frame Oil Filter Paper

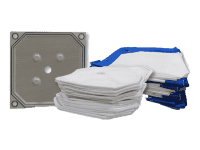

Filter Press Filter Cloth

Coolant filter paper with a non-woven media structure is made of PET or PP fibers. The filter paper has excellent filtration performance for filtering the metallic and non-metallic containment in coolant, guaranteeing the cleanliness of coolant and extending the coolant service life.

Grinding coolant filter paper can be supplied in rolls and is also available in sheets or die-cut shapes.

Grinding coolant filter paper is widely used in the coolant filtration system in metal processing.

Specifications

| Item | Thickness (mm) | Weight (g/m2) | Material | Longitudinal Strength (N/5cm) | Transverse Strength (N/5cm) | Air Permeability (L/m2s) | Filter precision (μm) |

|---|---|---|---|---|---|---|---|

| IBCFP-01 | 0.17±0.05 | 30±5 | Polyester | 60 | 15 | 3400 | 45–55 |

| IBCFP-02 | 0.26±0.05 | 40±5 | Polyester | 100 | 19 | 3000 | 36–45 |

| IBCFP-03 | 0.28±0.05 | 50±5 | Polyester | 110 | 25 | 2300 | 25–35 |

| IBCFP-04 | 0.30±0.05 | 60±5 | Polyester | 125 | 35 | 1800 | 15–25 |

| IBCFP-05 | 0.50±0.05 | 90±5 | Polyester | 220 | 52 | 650 | 8–12 |

| IBCFP-06 | 0.25–0.28 | 40 | Polyester | 100 | 60 | – | 40–50 |

| IBCFP-07 | 0.28–0.3 | 60 | Polyester | 120 | 80 | – | 30–40 |

| IBCFP-08 | 0.4–0.42 | 90 | Polyester | 135 | 96 | – | 10–15 |

| IBCFP-09 | 0.37–0.4 | 70 | Polyester | 190 | 65 | – | 18–22 |

| IBCFP-10 | 0.43–0.46 | 90 | Polyester | 230 | 85 | – | 12–18 |

| IBCFP-11 | 0.75–0.8 | 150 | Polyester | 360 | 140 | – | 5–10 |

| IBCFP-12 | 0.17–0.2 | 30 | Polypropylene | 90 | 50 | – | 50–60 |

| IBCFP-13 | 0.35–0.38 | 60 | Polypropylene | 190 | 105 | – | 15–25 |

| IBCFP-14 | 0.4–0.42 | 80 | Polypropylene | 210 | 130 | – | 10–15 |

Features

Applications

Coolant filter paper is widely used in gravity bed filters, vacuum filters, drum-type paper belt filters, deep bed paper belt filters, and other filtering equipment for coolant filtration, including:

Filter paper is widely used in the plate and frame oil filter machines for liquid filtration. It adopts cotton linter as raw material, which has a good absorbent filter, high compression strength, and filtration precision performance.

Specifications

| 180 × 180 | 185 × 185 | 187 × 187 | 190 × 190 |

| 200 × 200 | 234 × 234 | 235 × 235 | 240 × 240 |

| 245 × 245 | 250 × 250 | 270 × 270 | 280 × 280 |

| 280 × 285 | 285 × 285 | 290 × 290 | 295 × 295 |

| 296 × 296 | 298 × 298 | 295 × 300 | 300 × 300 |

| 325 × 325 | 340 × 340 | 400 × 400 | 440 × 440 |

| 500 × 500 | 600 × 600 | 700 × 700 | 900 × 900 |

| Φ 500 | Φ 600 | Φ 800 | Φ 1000 |

Features

Applications

The filter paper is widely used in petroleum, chemical, pharmaceutical, and other industries to filter out and separate the solid, semi-solid impurities from liquid and oils.

Filter media mainly contain transformer oil, turbine oil, lubricating oil, hydraulic oil, soluble organic liquid paraffin, oil analogy synthetic resin, sebacic acid dioctyl fat melting. And liquid medicine, dyes, drinks, plating liquid filtration.

Filter cloth is one of the key variables in the optimization of any liquid filtration application. We have a complete line of filter cloth for your filter press system to improve your production efficiency and reduce downtime. Our filter cloth varies in shapes, sizes, materials, and weave methods. All our filter cloths are carefully selected and optimized to guarantee good particle retention, clear filtrate, high flow rates, and dry filter cakes.

Specifications

Features

Applications

Our part numbers information is constantly revised.

Ask us if you don't see what you need.

Inquiry

Call us at +86-19831882282 or chat on WeChat with 0 second wait time

Custom Filter

Fill the custom form online and deliver it to us, you'll get the response within 4 hours

Design Filter

Tell us your requirement, and you will get a design to improve the existing performance within 4 hours

Disclaimer: Hengshui Yinbeier Hydraulic Filter Co., Ltd. is an independent industrial filter manufacturer which can supply filter elements that are functionally and dimensionally interchangeable with industrial filter elements from OEM Brands. Part numbers is for reference only. All trade names, service marks or registered trademarks are the properties of their respective owners. We does not claim to provide original filter elements of these brands.