Why Need Hydraulic Filter Elements?

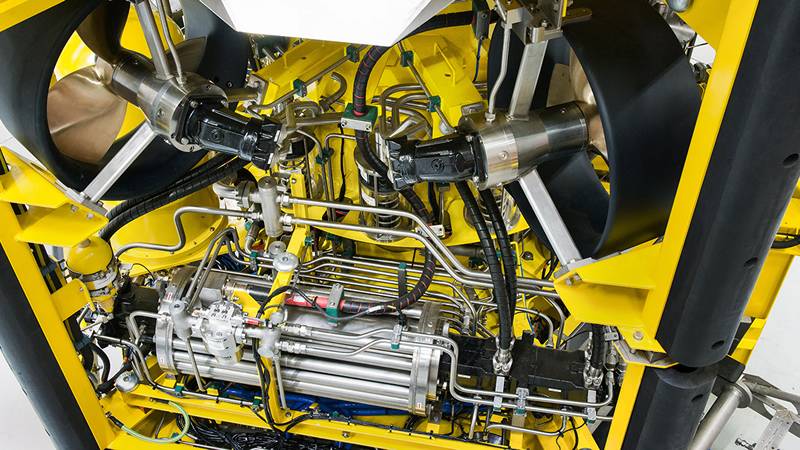

Hydraulic oil is the working medium to transfer energy in the hydraulic system. 80% of the shutdowns in the hydraulic system are due to contamination. If there is no filtration system, the hydraulic oil is not clean even if the oil is new. Each node has a hydraulic filter element for filtration, to ensure that the whole system is not harmed by pollutants, normal operation.

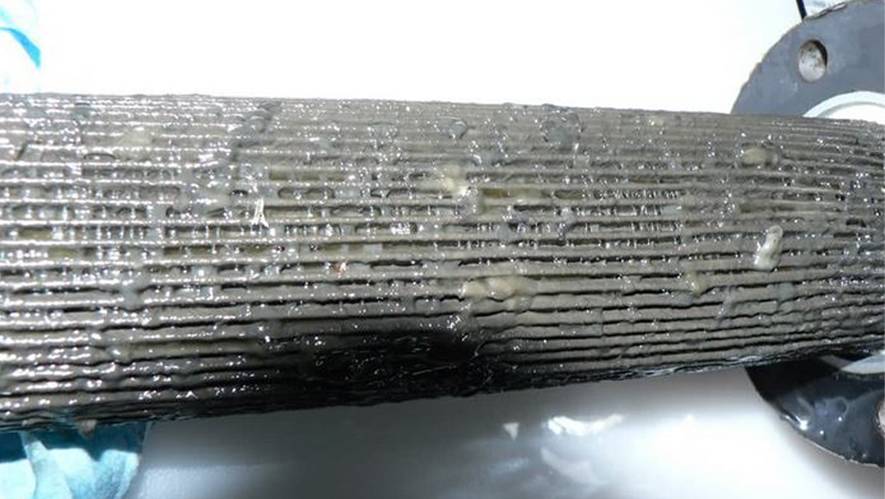

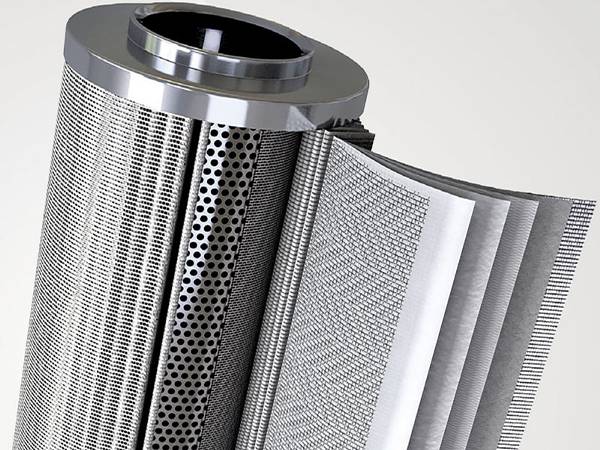

Hydraulic Filter Element Structures

The hydraulic filter elements are mainly composed of the support layer, filter layer, and end parts.

Hydraulic Oil Filter Element Specifications

What Types of Hydraulic Filter Elements Do We Have?

Standard hydraulic filter elements contain following types:

Different applications use one or other combined filter elements for production filtration.

What Are the Benefits of Hydraulic Filter Elements?

How to order the hydraulic filter elements?

If you wonder what you need to purchase, just supply the following data as more as possible, our professional sales will recommend the right elements for you.

If you have a brand and part number, just tell us and we will quote for you.

Contact Us