Why we need air compressor filter elements?

In the compressor air system, hard particles assault equipment and piping. This will generate more particles (scale, metal oxides and dirt). these particles may plug orifices of sensitive pneumatic instrumentation, wear out seals, erode system components, decrease air tool efficiency and even damage finished products.

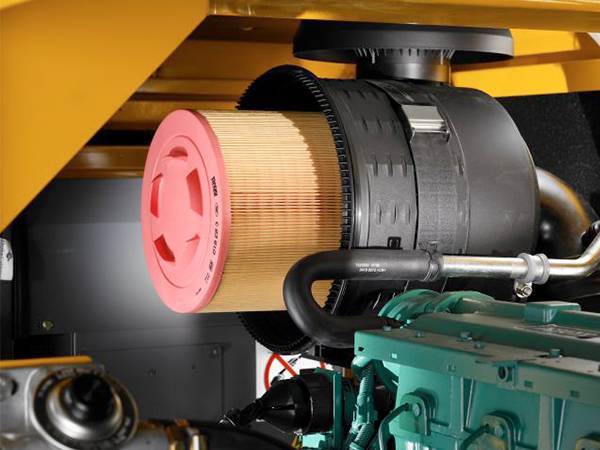

Air compressor filter element can maximally reduce and eliminate solid particles, oil and liquid in compressor air and guarantee the continuous supply of pure and high quality compressor air.

What types of air compressor filter element?

The air compressor filter mainly include air filter element, oil/gas separator filter element and oil filter elements.

Where air compressor filter elements are used?

The air compressor filter elements can be used in both double screw rod air compressor and reciprocating compressor.

And they are widely used in various fields, such as: