Why Need Compressed Air Line Filter Elements?

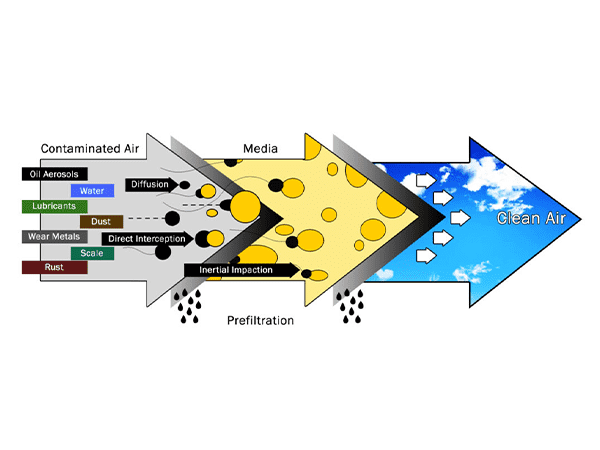

Compressed air is the main security energy in large-scale industrial production. While the larger particles will be removed by the air compressor filter elements itself, but the oil, water, and tiny particles containment will enter the equipment along with compressor air. Uncleaned compressor air can be very harmful to equipment, it may cause pipeline and core components breakage, increase downtime and reduce the equipment service life. Moreover, it will cause high maintenance and energy cost. So precision filtration of compressed air is particularly important.

What are the Functions of In-Line Filter Elements?

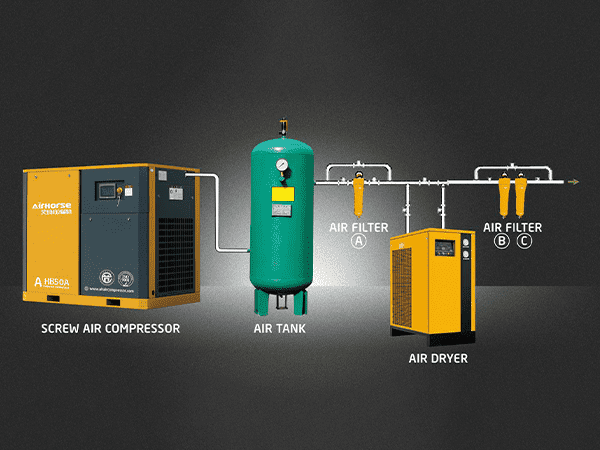

In-line filter elements are installed front and back of dryers in the compressed air system, they can help:

What Types of Compressed Air Line Filter Elements DO We have?

We can supply original and OEM compressed air line filter elements for customers, main brands include hankison, Atlas, Domnick Hunter, BEA and others.

You can browse and search the brands and part numbers or you can contact us for more brands and models of air line filter elements.

Where Line Filter Cartridges Are Used For?

The line filter cartridges are installed at the front and back of the dryers in compressed air system, including Regenerative desiccant dryers and refrigerated dryers.

They are widely used in: